How to Ensure Safety for Industrial Workers?

The issue of industrial accidents has risen to the forefront in recent months, with some companies opting for self-regulation and others establishing a formal board. What are some best practices for ensuring safety across all industries?

The “general safety rules in industry” are a set of guidelines that can be used to protect workers from injuries and other accidents.

Every manager or supervisor, particularly those engaged in industrial operations, should pay close attention to the safety of their personnel. It should, however, be at the top of every company’s priority list, regardless of their sector. Such rules should be in place by the management team to ensure that their workers are safe at work.

Furthermore, it is common knowledge that certain workplaces are riskier than others. They are the industries in which laborers are employed. When employees labor in an industrial environment, they are more likely to be injured than when they work on computers. However, if you manage or oversee a business where workers’ safety is a concern, you should take extra care to protect their safety.

We’ve got your back if you’re not sure how to protect the safety of personnel in an industrial environment. In this essay, we’ll go over some helpful hints for ensuring industrial safety.

Industrial Valves Installation

If you operate in a plant containing liquids, slurries, or gases, you’ll need to install industrial valves to keep your workers safe. The valves are devices that enable industrial attendants and supervisors safeguard safety by controlling gases, liquids, and slurries. The valves will regulate the flow of liquids and gases so that they do not flow too much or too little in comparison to what is necessary.

Every manager or supervisor, particularly those engaged in industrial operations, should pay close attention to the safety of their personnel. It should, however, be at the top of every company’s priority list, regardless of their sector. Such rules should be in place by the management team to ensure that their workers are safe at work.

Furthermore, it is common knowledge that certain workplaces are riskier than others. They are the industries in which laborers are employed. When employees labor in an industrial environment, they are more likely to be injured than when they work on computers. However, if you manage or oversee a business where workers’ safety is a concern, you should take extra care to protect their safety.

We’ve got your back if you’re not sure how to protect the safety of personnel in an industrial environment. In this essay, we’ll go over some helpful hints for ensuring industrial safety.

Industrial Valves Installation

If you operate in a plant containing liquids, slurries, or gases, you’ll need to install industrial valves to keep your workers safe. The valves are devices that enable industrial attendants and supervisors safeguard safety by controlling gases, liquids, and slurries. The valves will regulate the flow of liquids and gases so that they do not flow too much or too little in comparison to what is necessary.

Industrial valve actuators are used to place the valves in the proper position. The device guarantees that it remains in position and functions properly. Uncontrolled pressure is hazardous to both the workers and the environment as a whole. As a result, consider installing a valve to assure safety.

Provide Personal Protection Equipment

Heavy machinery and equipment may be found in a number of industrial facilities and warehouses. Employees must operate in close proximity to such equipment, which is a recipe for disaster. Individuals are provided with personal protective equipment by most manufacturing units to ensure that they take care of themselves while working and do not get wounded.

Industrial valve actuators are used to place the valves in the proper position. The device guarantees that it remains in position and functions properly. Uncontrolled pressure is hazardous to both the workers and the environment as a whole. As a result, consider installing a valve to assure safety.

Provide Personal Protection Equipment

Heavy machinery and equipment may be found in a number of industrial facilities and warehouses. Employees must operate in close proximity to such equipment, which is a recipe for disaster. Individuals are provided with personal protective equipment by most manufacturing units to ensure that they take care of themselves while working and do not get wounded.

They may wear such gear while working throughout the day or while using certain apparatus. Helmets, fireproof coats, gloves, heavy-duty boots, and other protective gear are examples. Employees’ safety gear is determined by the warehouse where they work. Not all jobs are created equal, and various jobs need different safety equipment.

Inform your employees on the importance of safety.

No matter how many pieces of safety equipment and procedures you put in place at your workplace, they will only be successful if the management, i.e. you, and your staff, allow them to operate effectively. To get the most out of the measure, you should follow it. It will assist if you explain the significance of safety to your coworkers and other employees, as this will guarantee that your whole team is on the same page.

However, no matter how many “dangerous” warnings you put up around equipment or in a certain region, if people disregard them, they will be in danger. Every person who works in the environment has to have a more safety-conscious mentality.

The importance of proper training cannot be overstated.

You can’t expect someone to follow a safety policy if they don’t know about it or don’t understand it. It is the manager’s obligation to ensure that everyone working in the sector is aware of and understands all safety procedures. This is accomplished by prioritizing good training.

They may wear such gear while working throughout the day or while using certain apparatus. Helmets, fireproof coats, gloves, heavy-duty boots, and other protective gear are examples. Employees’ safety gear is determined by the warehouse where they work. Not all jobs are created equal, and various jobs need different safety equipment.

Inform your employees on the importance of safety.

No matter how many pieces of safety equipment and procedures you put in place at your workplace, they will only be successful if the management, i.e. you, and your staff, allow them to operate effectively. To get the most out of the measure, you should follow it. It will assist if you explain the significance of safety to your coworkers and other employees, as this will guarantee that your whole team is on the same page.

However, no matter how many “dangerous” warnings you put up around equipment or in a certain region, if people disregard them, they will be in danger. Every person who works in the environment has to have a more safety-conscious mentality.

The importance of proper training cannot be overstated.

You can’t expect someone to follow a safety policy if they don’t know about it or don’t understand it. It is the manager’s obligation to ensure that everyone working in the sector is aware of and understands all safety procedures. This is accomplished by prioritizing good training.

The training should include both general safety procedures and procedures to be followed while dealing with particular machines. However, it would be beneficial if you kept them up to speed on the most recent safety measures, since they change on a regular basis. With such developments, you must ensure that all of your staff are at the top of their game.

Tell them how important it is to be proactive:

You may be really concerned about creating a safe workplace for all of your workers, but accidents can happen, and you and your team should be prepared for them. Furthermore, as a supervisor, you can’t concentrate on everyone at the same time since you only have one pair of eyes. As a result, whether you are present or not, staff should make it a point to look after themselves. It would be beneficial if you encouraged your team to foster a culture where they may report any harmful issues as soon as they become aware of them.

The training should include both general safety procedures and procedures to be followed while dealing with particular machines. However, it would be beneficial if you kept them up to speed on the most recent safety measures, since they change on a regular basis. With such developments, you must ensure that all of your staff are at the top of their game.

Tell them how important it is to be proactive:

You may be really concerned about creating a safe workplace for all of your workers, but accidents can happen, and you and your team should be prepared for them. Furthermore, as a supervisor, you can’t concentrate on everyone at the same time since you only have one pair of eyes. As a result, whether you are present or not, staff should make it a point to look after themselves. It would be beneficial if you encouraged your team to foster a culture where they may report any harmful issues as soon as they become aware of them.

When your staff do this, you should thank them and try to remedy the problem as quickly as feasible. This will assist you realize that your staff are aware of their concerns, and you should continue to encourage them to report such situations in the future.

Encourage your workers to take a break.

Employees who are weary are more likely to be hurt, according to reports. It suggests they haven’t taken a break in a long time, with the exception of the typical ones. They may fail to follow the safety rules given forth in the first place if they are tired, resulting in a number of unsafe scenarios where accidents occur. Fortunately, you can simply resolve this problem by giving your staff a few days off so that they may take a rest and return rejuvenated.

They will feel well-rested and energized when they return after a break, ready to focus on their task. You won’t have to be concerned about losing money if your staff take a vacation since you’ll be saving money regardless. You will save money since you will not have to pay for any injuries. Furthermore, when you return, you will notice an increase in your colleagues’ productivity.

Conclusion

Safety precautions are not just important in preventing injuries to your staff. Furthermore, implementing safety precautions at your business will significantly increase employee morale. To get the most advantages, get started right away.

Watch This Video-

The “types of safety precautions” are the type of safety precautions that can be taken to ensure the safety for industrial workers.

Frequently Asked Questions

How do you ensure industrial safety?

A: It is my responsibility to ensure industrial safety.

How can you ensure work safety as an employee?

How would you ensure safety and health of workers in a manufacturing industry?

A: In a manufacturing industry, safety and health can be ensured by various means. Ensuring worker safety is the responsibility of the owner or manager of that company. It would help if employees were educated in using proper tools and equipment to avoid accidents from happening.

Related Tags

- importance of safety in manufacturing industry

- safety in manufacturing plants

- safety precautions examples

- general safety rules in the workplace pdf

- safety rules in company

Ultimate 3 Sites For Purchasing Instagram Followers

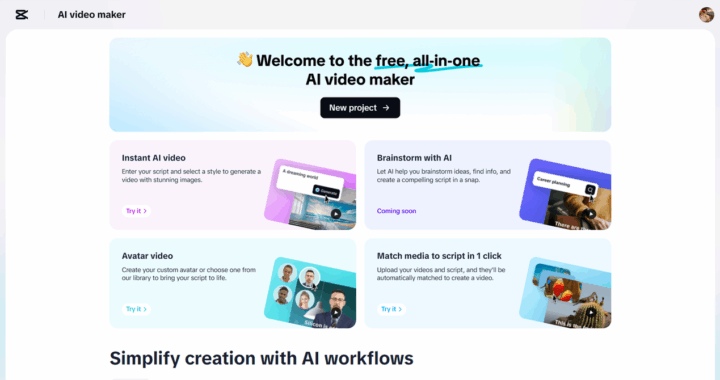

Ultimate 3 Sites For Purchasing Instagram Followers  Use AI Video Maker to Launch Seasonal Greetings That Wow

Use AI Video Maker to Launch Seasonal Greetings That Wow  How to Choose the Perfect Homecoming Dress

How to Choose the Perfect Homecoming Dress