Mining Operations Demand Reliable Gearboxes (Here’s How to Ensure It)

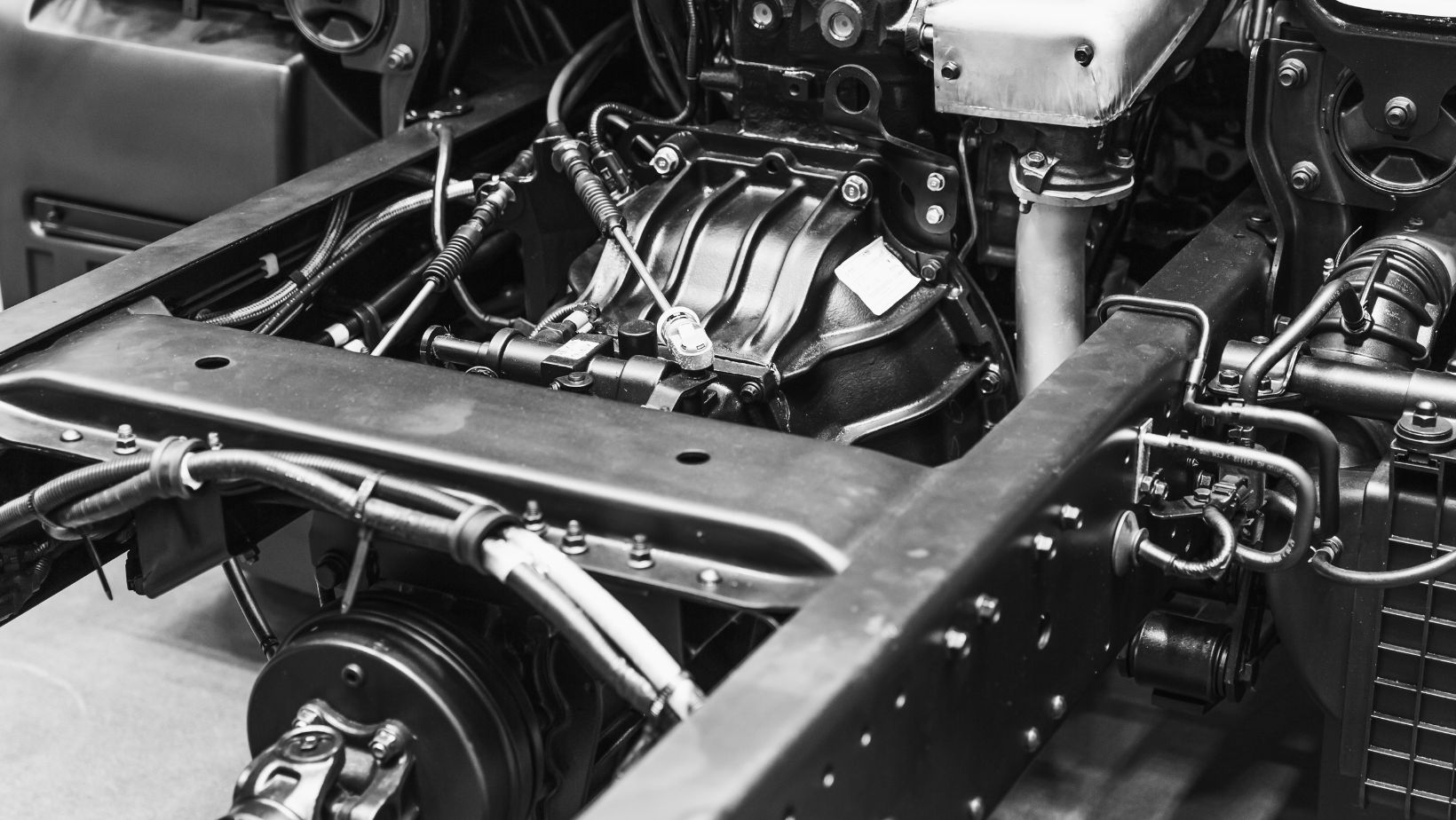

When a mining gearbox fails, it doesn’t just stop machinery it stops the entire operation cold. Production grinds to a halt, repair costs skyrocket, and safety risks escalate in seconds. In an environment where every hour of downtime cuts deep into profitability, reliability isn’t a nice-to-have, it’s a lifeline. That’s why forward-thinking maintenance teams are shifting away from reactive fixes and embracing proactive, precision-engineered repair methods. By strengthening critical components before problems surface, mines can stay ahead of catastrophic failures, protect their crews, and keep every gearbox performing under relentless, heavy-load conditions.

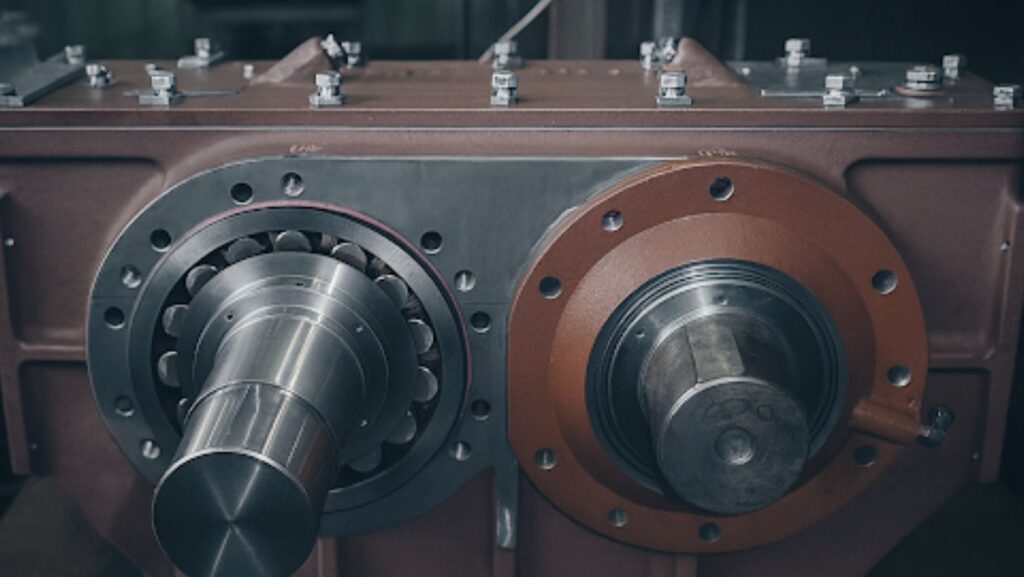

Why Gearbox Reliability Is Critical in Mining Operations

Every minute of downtime in mining leads to lost productivity. Gearboxes sit at the centre of essential equipment, from conveyors to crushers and a single failure can bring an entire production line to a standstill. Reliable gearboxes deliver smooth torque transfer, stable output, and safer performance under extreme loads. In a fiercely competitive mining landscape, equipment reliability is no longer just a mechanical concern, it’s a strategic business priority. By investing in proactive maintenance and early diagnostics, operators can maximise uptime ensuring operations run at peak efficiency where it matters most.

Why Mining Gearboxes Fail: The Most Common Root Causes

Mining gearboxes operate under relentless pressure like constant dust exposure, extreme heat, heavy loads, and intense vibration, all of which accelerate wear and shorten component life. Contaminants like dust and moisture quickly degrade lubricants and corrode internal parts, while overloading or misalignment places uneven stress on gears and bearings.

Inadequate or inconsistent lubrication allows friction and operating temperatures to spike, worsening damage over time. Even small oversights can create a chain reaction that leads to major equipment failure and stalled production. By understanding these root causes, maintenance teams can act early with scheduled inspections, precision alignment, and quality repair work to prevent costly unplanned downtime in demanding mining environments.

Proven Strategies to Maximise Gearbox Lifespan in Mining

Long-term gearbox reliability starts with disciplined, data-driven maintenance practices. Routine inspections supported by vibration monitoring, temperature tracking, and oil analysis allow teams to detect early signs of wear long before failures develop. Proper alignment during installation and periodic recalibration help prevent mechanical strain that accelerates gear and bearing damage. Maintaining correct lubrication, both in volume and quality, minimises friction and overheating under heavy loads. When wear does occur, expert welding, and component rebuilding can restore structural integrity without the cost of full replacement. By combining preventive care with skilled servicing, mining operations can significantly extend gearbox life, and maintain consistent production in harsh, high-demand environments.

Partnering with the Right Engineering Experts

Even the best maintenance plan relies on the right partner to execute it. Choosing an engineering team with specialised expertise in gearbox repairs ensures every component meets the highest standards of precision and durability. Berg Engineering combines decades of experience with advanced repair technologies to restore and strengthen mining equipment, from small-scale repairs to complete overhauls. Their end-to-end capability for inspection, machining, testing, and welding reduces turnaround times and guarantees quality control.

Don’t Wait for the Breakdown

Unplanned failures cost more than just repair bills—they disrupt production, compromise safety, and strain resources. Proactive maintenance and expert servicing are investments in long-term reliability, not expenses to postpone. By partnering with specialists, mining operators can strengthen gearbox performance extend equipment life

APIs Unlock Online Gambling’s Future in 2026: Blockchain Transforms Trust

APIs Unlock Online Gambling’s Future in 2026: Blockchain Transforms Trust  Why 24/7 Threat Monitoring Remains Out of Reach for Most Teams

Why 24/7 Threat Monitoring Remains Out of Reach for Most Teams  Online Betting Platform Guide 77bet: Characteristics and User Interface

Online Betting Platform Guide 77bet: Characteristics and User Interface