The Evolution of Aviation Engine Components and Their Role in Modern Flight

Aviation has come a long way since the Wright brothers’ first powered flight in 1903. Over the past century, aircraft engines have undergone massive advancements in efficiency, reliability, and sustainability. From piston engines to modern turbofans, the development of aviation engine components has played a crucial role in shaping the aviation industry.

The Early Days of Aircraft Engines

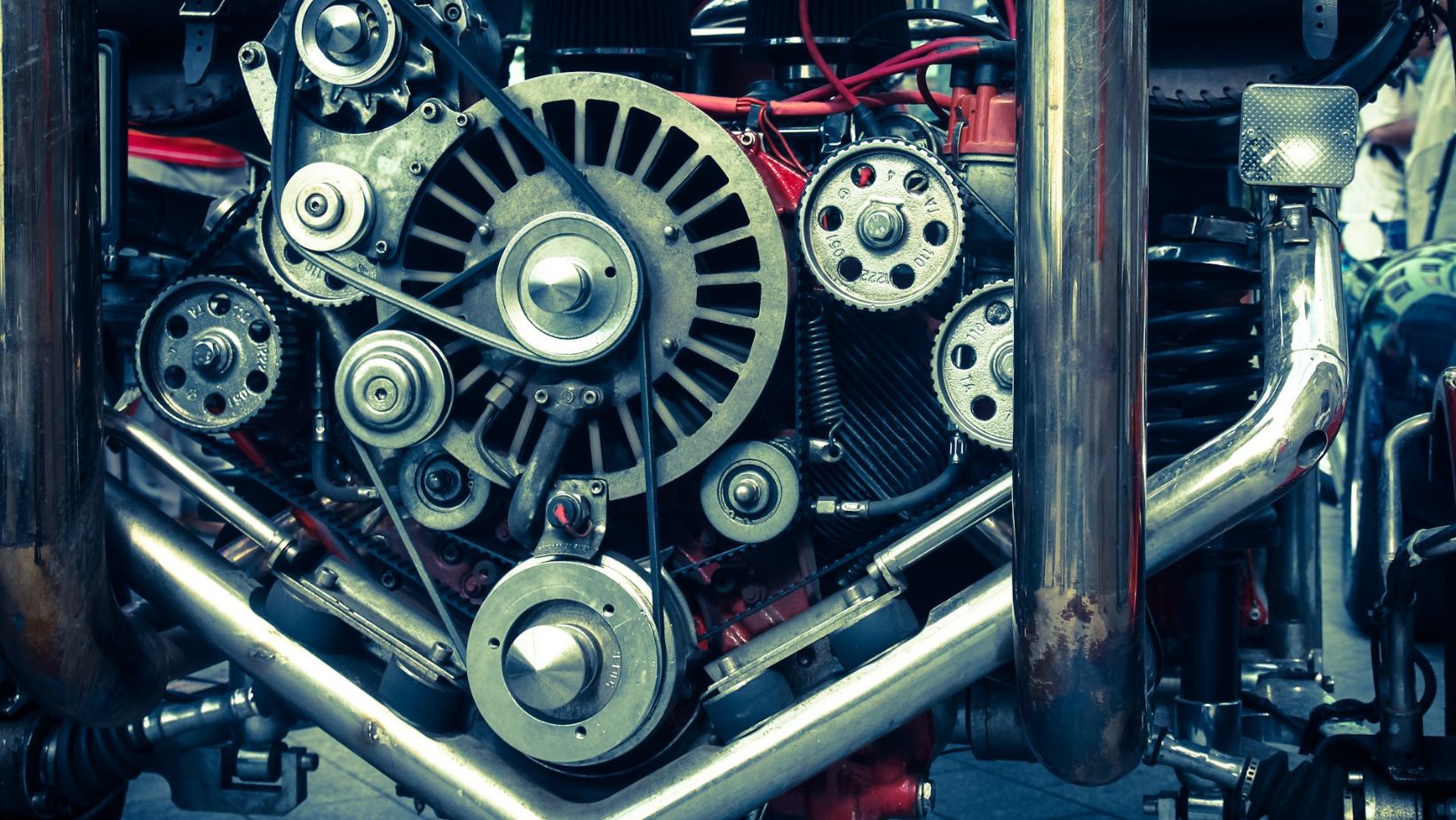

In the early 20th century, aircraft engines were rudimentary, primarily utilizing piston engines similar to those found in automobiles. These engines relied on simple mechanical systems to generate thrust. During World War I and World War II, advancements in engineering led to more powerful radial engines, which improved aircraft performance and expanded aviation’s role in warfare and transportation.

As aviation technology progressed, engineers sought ways to improve fuel efficiency and increase the power-to-weight ratio of aircraft engines. The result was the development of jet propulsion, which revolutionized air travel.

The Advent of Jet Engines

Jet engines changed the landscape of aviation in the mid-20th century. The first operational jet aircraft, the German Messerschmitt Me 262, demonstrated the potential of jet propulsion. The shift from piston engines to jet engines allowed for higher speeds, greater altitude capabilities, and improved efficiency.

Jet engines work on the principle of compressing air, mixing it with fuel, and igniting the mixture to produce thrust. Key aviation engine components such as compressors, turbines, and combustion chambers became the foundation of modern air travel. As these components evolved, engines became more reliable and fuel-efficient.

Advancements in Aviation Engine Components

1. Compressor Technology

Modern jet engines utilize axial-flow compressors, which efficiently compress incoming air to increase thrust generation. These compressors feature multiple stages of rotating blades that progressively compress the air before it enters the combustion chamber. Advancements in materials, such as titanium alloys and composite materials, have led to lighter and more durable compressor blades.

2. Turbine Efficiency

Turbines play a critical role in converting energy from combusted fuel into mechanical work. High-pressure turbines extract energy from hot gases and drive the compressor, while low-pressure turbines contribute to propulsion. The use of ceramic matrix composites (CMCs) has significantly improved turbine efficiency by reducing weight and increasing heat resistance.

3. Combustion Chamber Innovations

The combustion chamber is where fuel is burned to generate thrust. Modern designs aim to improve fuel efficiency while minimizing emissions. Lean-burn combustors and advanced cooling techniques help reduce nitrogen oxide emissions, making engines more environmentally friendly.

4. Materials and Manufacturing Advancements

Advancements in materials science have led to the development of stronger, heat-resistant, and lightweight components. Additive manufacturing, also known as 3D printing, allows engineers to create complex engine parts with reduced material waste and improved performance. This technology is paving the way for the next generation of efficient and durable aviation engines.

The Role of Aviation Engine Components in Sustainability

With growing concerns about climate change and carbon emissions, the aviation industry is actively working on sustainable propulsion systems. Many manufacturers are investing in hybrid-electric propulsion, sustainable aviation fuels (SAFs), and hydrogen-powered engines to reduce the environmental impact of flight.

Electric aircraft are in the early stages of development, with companies like Rolls-Royce and Airbus working on prototypes for short-haul flights. The goal is to integrate electric propulsion with advanced aviation engine components to create a new era of clean aviation.

Challenges and Future Trends in Aviation Engines

Despite significant advancements, the aviation industry faces several challenges:

- Fuel Efficiency: Reducing fuel consumption remains a priority. Ongoing research focuses on ultra-efficient engine designs, such as open-rotor and geared turbofan engines.

- Emissions Reduction: Governments and organizations worldwide are implementing stricter regulations to lower carbon emissions. Sustainable aviation fuels and alternative propulsion methods are at the forefront of this effort.

- Noise Reduction: Innovations in engine design, such as chevron nozzles and quieter fans, aim to reduce noise pollution from aircraft.

The future of aviation engines may also include the integration of artificial intelligence (AI) to optimize performance and predictive maintenance. AI-driven analytics can help airlines improve fuel efficiency and reduce operational costs.

Conclusion

The evolution of aviation engine components has been instrumental in shaping modern air travel. From early piston engines to high-tech jet propulsion systems, advancements in technology have continually improved efficiency, reliability, and sustainability. As the aviation industry moves toward greener alternatives, the role of innovative engine components will become even more critical.

With ongoing research and technological breakthroughs, the future of aviation looks promising. The continued evolution of propulsion systems will ensure that air travel remains efficient, environmentally responsible, and accessible to future generations.

Additional Resources

- NASA’s Aeronautics Research on Sustainable Aviation

- Federal Aviation Administration (FAA) Research on Engine Technologies

Slot Gacor Explained Through Game Design and Probability

Slot Gacor Explained Through Game Design and Probability  HVAC Tech Tips: Your Ultimate Guide to Mastering HVAC Systems

HVAC Tech Tips: Your Ultimate Guide to Mastering HVAC Systems  Linus Tech Tips Age: The Journey of a Tech Phenomenon

Linus Tech Tips Age: The Journey of a Tech Phenomenon